With immense success in both retail and industrial divisions in the chocolate industry, Theocom entered the cone manufacturing business under the brand name CHOCOLO. Theocom is a Pvt. Ltd. company specializing in the manufacturing of Sugar Rolled Cone, Wafer Cone primarily used in the ice-cream industry for Automatic Rolled Sugar Cone Production Line.

With immense development and growth over the last 6 years, Theocom has become a well-known manufacturer for sugar rolled and wafer cones. Every cone we manufacture is high in quality, taste and precision. Its perfection rolled into an edible cone!

The batter for all cones is mixed in large vat-like mixers and stored in coolers. Air compressors blow the dry ingredients into the mixers. Separate mixers and coolers are used to combine and store the batter for cake cones and for waffle and sugar cones together. The air compressors that pump in all ingredients are computer-controlled so the recipe for each cone is correct. Computers also control all the other machines in the factory; in the mixing area, they tell the compressors when the coolers are running low on batter, so the next batch is mixed automatically.

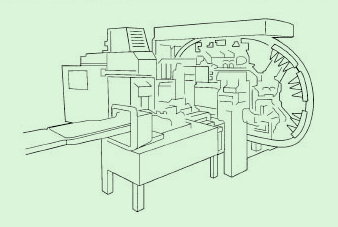

From the coolers, batter is pumped to storage tanks next to the baking ovens. It is then pumped through a pipe. Waffle cone batter is pumped batter flows onto plates much like the bottom plates of waffle irons. The pumping system applies a pre-measured amount of batter to either the mold or the plate. Waffle and sugar cones bake for about 82 seconds, but they take longer to finish because they have to be shaped. The flat, hot, baked circles are rolled into cone shapes by specialized cone-rolling machines in a process that takes about 20 seconds. These cones cannot be handled for packing until they are completely cooled, and they are air-cooled for 2 minutes. Cooling makes the cones firm to hold their shape.

From the coolers, batter is pumped to storage tanks next to the baking ovens. It is then pumped through a pipe. Waffle cone batter is pumped batter flows onto plates much like the bottom plates of waffle irons. The pumping system applies a pre-measured amount of batter to either the mold or the plate. Waffle and sugar cones bake for about 82 seconds, but they take longer to finish because they have to be shaped. The flat, hot, baked circles are rolled into cone shapes by specialized cone-rolling machines in a process that takes about 20 seconds. These cones cannot be handled for packing until they are completely cooled, and they are air-cooled for 2 minutes. Cooling makes the cones firm to hold their shape.

Although cone-making is computer-controlled, workers are essential to quality control. The correct addition of ingredients is the most obvious quality control step, but throughout the process specially trained quality control inspectors watch cone making and baking, taste-test cones occasionally, and reject any that are misshapen, broken, or over/under-cooked. Whole cones are also removed from the process and cut and broken apart to check that cones are truly perfect inside and out.